A-pillar repair combines traditional craftsmanship and advanced technology for specialized automotive restoration. Skilled technicians use laser cutting and robotic welding, digital design software, and precise measurement systems to ensure accurate, efficient repairs maintaining safety and aesthetic standards. Technological integration modernizes car body shop operations, reducing labor costs, minimizing errors, and facilitating data collection for fleet managers to optimize vehicle performance and safety.

“In today’s fleet management landscape, efficient and cost-effective A-pillar repair is paramount. This article delves into the significance of A-pillar repair techniques, exploring how these crucial processes can be enhanced through technology integration. We dissect the benefits, focusing on improved efficiency and long-term gains for fleet operations. By understanding the latest repair methods and technological advancements, managers can optimize their strategies, ensuring a robust and sustainable fleet.”

- Understanding A-Pillar Repair Techniques

- Technology Integration: Enhancing Efficiency

- Long-Term Benefits for Fleet Management

Understanding A-Pillar Repair Techniques

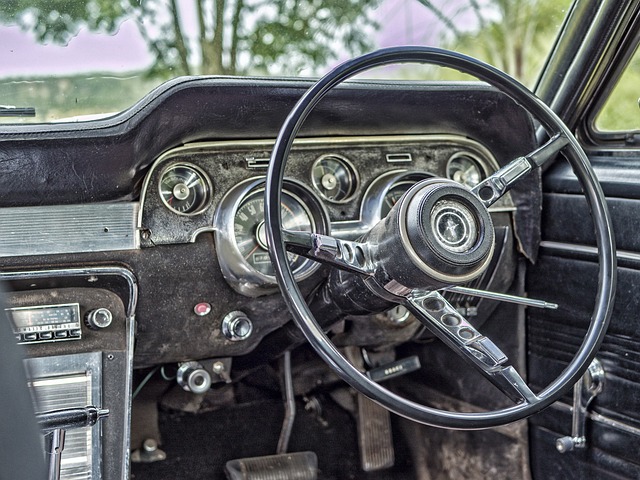

A-pillar repair is a specialized process within the automotive restoration field, focusing on restoring or replacing the structural support columns (pillars) found in car bodies. These pillars are integral to vehicle safety and rigidity, making their repair a critical aspect of collision repair. Understanding A-pillar repair techniques involves recognizing that each pillar is unique in design and composition, requiring skilled technicians to assess and address specific damage. Modern repair methods often employ advanced technology, such as laser cutting and robotic welding, for precision and accuracy, ensuring minimal disruption to the vehicle’s overall structural integrity.

Automotive restoration professionals use a combination of traditional craftsmanship and innovative technology to perform A-pillar repairs effectively. The process involves meticulous disassembly, careful inspection, and precise fabrication to match the original specifications. With advancements in car body restoration techniques, the integration of digital design software allows for computer-aided cutting and shaping, enhancing both efficiency and accuracy during the repair process. This level of detail ensures that vehicles not only look their best but also maintain optimal safety standards after collision repair.

Technology Integration: Enhancing Efficiency

Technology integration plays a pivotal role in modernizing A-pillar repair processes within car body shops. By implementing advanced tools and software, vehicle repair services can streamline their operations, leading to enhanced efficiency. For instance, digital measurement systems provide precise data, eliminating manual estimation errors commonly associated with traditional methods. This accuracy ensures that every A-pillar replacement or repair is tailored to the specific vehicle’s needs, resulting in better structural integrity and aesthetic alignment.

Additionally, automation in certain tasks can significantly reduce labor costs and turnaround times. Automated welding machines, for example, can handle intricate repairs with speed and consistency, allowing auto maintenance technicians to focus on more complex aspects of the job. This integration not only improves productivity but also contributes to a safer work environment by reducing manual errors and exposure to hazardous materials during A-pillar repair processes.

Long-Term Benefits for Fleet Management

The long-term benefits of A-pillar repair extend far beyond immediate visual improvements. For fleet managers, this process offers a strategic opportunity to enhance overall vehicle performance and safety, which is particularly crucial for commercial fleets. Regular A-pillar maintenance can prevent more costly repairs down the line, as damage to these structural components can compromise the integrity of the entire vehicle frame over time. By prioritizing A-pillar repair, fleet operators can reduce the frequency of auto glass replacement and minimize disruptions caused by damaged windshields.

Furthermore, integrating advanced technology into the A-pillar repair process allows for enhanced fleet management capabilities. Modern repair techniques, such as precision welding and high-quality auto body services, ensure that vehicles return to service faster with superior structural strength. This integration also facilitates data collection and analysis, enabling fleet managers to gain valuable insights into vehicle performance and identify areas for optimization. For example, advanced sensors can monitor the impact of repairs on a Mercedes Benz repair, ensuring that every vehicle meets the highest safety standards.

A-pillar repair and technology integration are transforming fleet management. By understanding advanced repair techniques and embracing digital solutions, businesses can achieve enhanced efficiency, reduced costs, and improved safety. These strategies not only benefit individual vehicles but also contribute to the overall success and sustainability of transportation operations. Incorporating these innovations is a step towards a more efficient and resilient future for fleet management.