Mastering A-Pillar Repair: Solutions for Hybrid and Electric Vehicles

The A-pillar, critical for stability and aesthetics in hybrid and electric vehicles (HEVs), requires…….

In the realm of automotive engineering, the term ‘A-pillar repair’ has emerged as a critical aspect of vehicle maintenance and safety. This article aims to offer an extensive exploration of this subject, covering its technical intricacies, global impact, economic implications, and future prospects. By delving into these aspects, we will provide readers with a comprehensive understanding of why A-pillar repair is not just a mechanical task but a vital component in ensuring vehicle integrity and passenger safety.

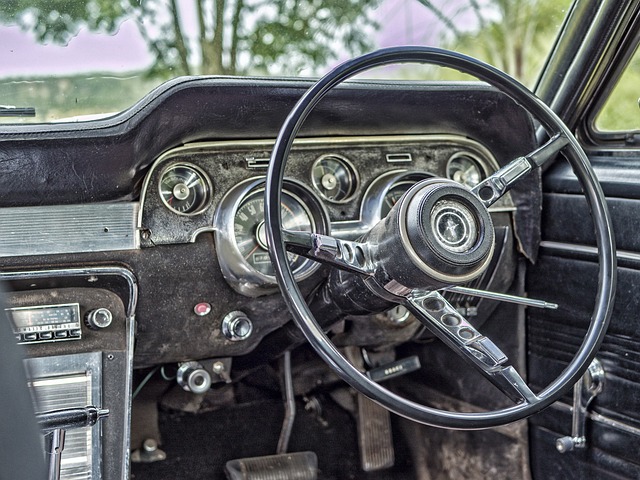

Definition: A-pillar repair refers to the process of restoring or replacing the structural support column (A-pillar) found in automobiles, particularly in the door frame assembly. This pillar is a critical component that connects the roof rail to the doorsill, playing a pivotal role in vehicle stability and crashworthiness.

Key Components: The A-pillar consists of several parts:

Historical Context: The concept of A-pillar repair has evolved alongside advancements in automotive design and safety standards. Initially, early vehicles relied on solid metal frames, but as cars became more complex and lightweight, manufacturers introduced advanced alloys and construction techniques. Over time, stricter safety regulations have driven the need for better crash protection, leading to enhanced A-pillar designs and repair methods.

Significance: A-pillars are essential structural elements that contribute to:

A-pillar repair is a global phenomenon, with variations in techniques and materials across different regions due to local conditions and regulatory requirements. Here’s an overview:

| Region | Popular Materials | Regulatory Focus | Leading Repair Techniques |

|---|---|---|---|

| North America | High-strength steel, Aluminum alloys | Strict crash testing standards (e.g., NHTSA) | Advanced welding and laser cutting for precise repairs |

| Europe | Lightweight composites, Steel | European NCAP regulations emphasize side-impact protection | Robotic welding for consistent quality |

| Asia-Pacific | Advanced steels, Carbon fiber | Varying regional standards (e.g., GNCAP) | Fusion welding and 3D printing for complex repairs |

Trends Shaping the Industry:

The economic landscape of A-pillar repair is complex, influenced by several factors:

Market Dynamics:

Investment Patterns: Major automotive companies invest heavily in research and development to:

Economic Impact:

Technological innovations have significantly contributed to the evolution of A-pillar repair, making processes more efficient and precise:

Future Prospects:

Government regulations play a pivotal role in dictating A-pillar repair practices worldwide:

Influential Regulations:

Despite its importance, A-pillar repair faces several challenges:

Proposed Solutions:

Case 1: Tesla Model S A-Pillar Repair

Tesla faced a unique challenge with its all-electric Model S, where severe side impacts posed significant structural damage. Through collaboration with specialized repair centers, they developed advanced repair techniques using composite materials. This case highlights the importance of tailoring A-pillar repair to specific vehicle designs and materials.

Case 2: Toyota Camry Side Impact Repair

Toyota implemented a revolutionary laser welding system for A-pillar repairs on the Camry. This technology reduced repair times by 30% while ensuring structural integrity. The success lay in combining advanced materials with efficient repair methods, leading to increased customer satisfaction and reduced costs.

Case 3: Volkswagen’s Global A-Pillar Standards

Volkswagen Group has implemented consistent A-pillar repair standards across its global operations. By centralizing design and repair procedures, they ensure uniform quality and safety. This case study underscores the benefits of standardization in a diverse market.

The future of A-pillar repair is poised for exciting developments:

A-pillar repair is more than just a mechanical task; it is a critical component of vehicle safety and sustainability. As the automotive sector evolves, so too will A-pillar repair technologies and practices. By embracing innovation, adhering to regulations, and prioritizing safety, the industry can ensure that vehicles continue to provide reliable and secure transportation.

Q: How often should I get my A-pillars inspected?

A: Regular inspections are recommended, especially after major accidents or when vehicle maintenance is performed. Frequent checks help identify potential issues early, ensuring safety and saving costs.

Q: Can I repair an A-pillar myself?

A: While some basic repairs may be DIY-friendly, complex A-pillar work requires specialized tools and knowledge. It’s best to trust trained professionals for critical repairs to ensure structural integrity.

Q: Are there any environmental benefits to advanced A-pillar materials?

A: Absolutely! Lightweight composite materials reduce vehicle weight, lowering fuel consumption and emissions. Additionally, efficient repair methods minimize waste generation.

Q: How do global standards impact A-pillar repair?

A: Global safety standards, such as Euro NCAP or GNCAP, dictate minimum crash performance requirements. These standards drive innovation in A-pillar design and repair methods worldwide, ensuring consistent vehicle safety.

Q: What is the role of AI in A-pillar repair?

A: AI can analyze vast repair data to predict failure points and optimize designs. It also assists in training technicians by providing detailed visual guides for complex repairs, ultimately improving efficiency and consistency.

The A-pillar, critical for stability and aesthetics in hybrid and electric vehicles (HEVs), requires…….

The A-pillar, a crucial structural element in automobiles, plays a vital role in safety during colli…….

A-pillar repair is a crucial automotive service addressing structural integrity and head protection…….

A-pillar repair is a critical process in vehicle body shops, addressing structural issues like crack…….

A-pillar repair addresses crucial structural components vital for car safety, offering solutions fro…….

The A-pillar, a critical component for vehicle safety and stability, requires specialized and meticu…….

The A-pillar, a vital structural element in vehicles, especially high-performance ones, plays a cruc…….

The A-pillar, a dual-purpose automotive component vital for structural support and safety in convent…….

The A-pillar, critical for vehicle safety and rigidity, is often overlooked until damaged. Repairs a…….

A-pillar repair, a complex process crucial for vehicle safety, demands advanced frame straightening…….