A-pillar repair is a critical safety component in vehicle collision repair and classic car restoration, requiring specialized knowledge and parts. Effective parts management through strong supplier relationships, digital inventory systems, and strategic planning ensures accessibility of authentic replacement parts while minimizing customer wait times, boosting shop profitability. Structured workflows, proactive communication, and partnerships are vital for swift, efficient, and reliable A-pillar repair processes in automotive maintenance.

In today’s competitive automotive landscape, efficient A-pillar repair and parts availability management are crucial for maintaining vehicle safety and customer satisfaction. This comprehensive guide delves into the essential aspects of A-pillar repair, exploring strategies that cater to understanding unique repair requirements, optimizing parts availability, and streamlining processes for timely repairs. By implementing these tactics, automotive professionals can ensure superior service quality and reduced downtime.

- Understanding A-Pillar Repair Requirements

- Strategies for Effective Parts Availability Management

- Streamlining Processes to Ensure Timely Repairs

Understanding A-Pillar Repair Requirements

Understanding A-Pillar Repair Requirements

A-pillar repair is a critical component of vehicle maintenance and safety, especially for those involved in collision repair or classic car restoration. The A-pillar, which connects the roof to the windshield, plays a vital role in structural integrity and must be meticulously repaired to ensure the vehicle’s overall safety and performance. Proper A-pillar repair requires specialized knowledge and equipment due to its intricate design and location.

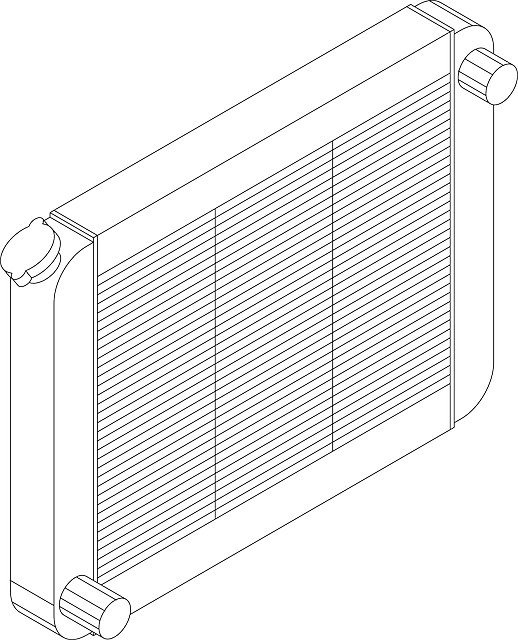

In collision repair centers, accurate assessment of A-pillar damage is essential before initiating any repairs. This includes identifying cracks, bends, or deformations that could compromise structural stability. For classic car restoration projects, the process may involve sourcing authentic replacement parts to maintain historical accuracy while still adhering to modern safety standards. Effective parts availability management ensures that all necessary components, including those for A-pillar repair, are readily accessible when needed.

Strategies for Effective Parts Availability Management

Effective parts availability management is a cornerstone for any successful auto body shop or collision repair shop. It involves implementing strategic initiatives to ensure that essential A-pillar repair parts are readily accessible when needed. One key strategy is to maintain strong relationships with reliable suppliers and distributors. By fostering partnerships, repair shops can secure consistent access to high-quality parts at competitive prices. Regular communication with these suppliers allows for advanced notice of stock arrivals and potential delays, enabling proactive decision-making.

Additionally, adopting a robust inventory management system is crucial. This involves utilizing technology to track part quantities, locations, and expiration dates. Digital tools can streamline the ordering process, prevent stockouts, and optimize shelf space within the workshop. By minimizing lead times for part procurement, auto body shops can enhance their service efficiency. Efficient parts availability management not only reduces customer wait times but also contributes to the overall success and profitability of the collision repair shop.

Streamlining Processes to Ensure Timely Repairs

In the realm of automotive maintenance, efficient A-pillar repair processes are paramount to ensuring swift and effective car collision repair. Streamlining these procedures allows for a seamless transition from assessment to restoration, minimizing downtime for both vehicles and their owners. By implementing structured workflows, workshops can enhance productivity while maintaining meticulous record-keeping. This involves cataloging specific parts required for A-pillar repair, anticipating potential shortages, and fostering strong relationships with reliable suppliers, thereby ensuring an ample stock of necessary components.

Efficient management of parts availability is the linchpin in successful vehicle repair and car restoration initiatives. It requires proactive planning, constant communication, and strategic partnerships to address common challenges like part obsolescence or limited supplier inventory. Through these measures, repair shops can guarantee that essential A-pillar parts are readily available when needed, facilitating timely interventions during car collision repair operations.

A-pillar repair and parts availability management are essential aspects of vehicle maintenance that require a strategic approach. By understanding the unique challenges and implementing effective strategies, car dealerships and workshops can streamline their processes, reduce downtime, and enhance customer satisfaction. Prioritizing A-pillar repair, coupled with efficient parts procurement and inventory management, is key to staying competitive in the automotive industry.