A-pillar repair begins with assessing structural integrity and aesthetics, prioritizing critical damage. Regular maintenance prevents future issues. Gather specific tools and materials for a smooth process. Implement structured procedures for consistent, accurate repairs, ensuring original specifications. Collision centers can efficiently handle high volumes while maintaining precision.

Efficient workflow management in automotive repair, specifically focusing on A-pillar repair, is crucial for keeping vehicles on track and customers satisfied. This guide offers actionable tips to streamline your process. Start by assessing A-pillar damage and prioritizing repairs based on severity and vehicle safety. Ensure you have all necessary tools and materials within reach to avoid delays. Implement a structured repair process for consistency in quality and efficiency.

- Assess A-Pillar Damage and Prioritize Repairs

- Gather Necessary Tools and Materials Efficiently

- Implement Structured Repair Process for Consistency

Assess A-Pillar Damage and Prioritize Repairs

When addressing A-pillar repair, the first step is to thoroughly assess the damage. Inspect both the structural integrity and aesthetic condition of the A-pillar. Look for cracks, dents, or deformations that could compromise the pillar’s strength and the overall safety of the vehicle. Prioritize repairs based on severity: address critical structural damage immediately to ensure driver and passenger safety. For cosmetic issues, like chips or small dents, plan a timeline for auto glass replacement or painting services in a vehicle body shop.

Regular auto maintenance plays a vital role in preventing future A-pillar repair needs. Keep an eye out for signs of wear and tear and address them promptly. Regular checks can help identify potential issues early on, making repairs less complex and costly. Remember, timely intervention through auto glass replacement or structural repairs is key to maintaining the vehicle’s integrity and preserving its value.

Gather Necessary Tools and Materials Efficiently

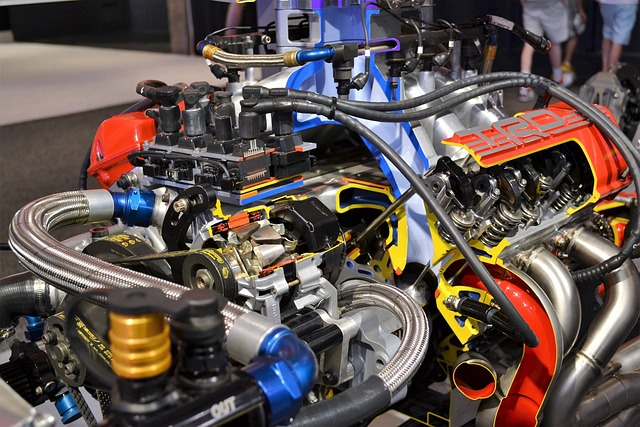

Before initiating any A-pillar repair, it’s imperative to gather all necessary tools and materials efficiently. This preparation is a cornerstone of ensuring a smooth workflow during the car bodywork services process. A well-stocked toolkit tailored for auto glass repair and car body repair will streamline your work, minimizing delays and potential errors.

Consider the specific requirements of the A-pillar repair job at hand. Tools such as precision screwdrivers, specialized hammers, and high-quality adhesives are often necessary. Material choices vary based on the extent of damage; however, having a variety of replacement parts, including panels, seals, and finishes, readily available can significantly enhance your efficiency during car body repair tasks.

Implement Structured Repair Process for Consistency

Implementing a structured repair process is essential for maintaining consistency in A-pillar repair procedures. This involves creating detailed step-by-step guidelines that every technician follows precisely. By standardizing the repair approach, you ensure that each A-pillar is restored to its original specifications, minimizing variations across different vehicles and ensuring quality control.

A well-defined process begins with an assessment of the damage, followed by gathering the necessary tools and materials specific to A-pillar repairs. This structured method streamlines workflow management, allowing collision centers or vehicle body repair shops to efficiently handle a high volume of repairs while maintaining accuracy and precision in every step of the A-pillar repair process.

Efficient A-pillar repair management involves assessing damage, gathering tools, and implementing a structured process. By prioritizing repairs and ensuring you have all necessary materials, you can streamline your workflow for consistent and effective results. Remember, a well-managed A-pillar repair process is key to maintaining vehicle safety and structural integrity.